- Home

- Custom Automotive Interior

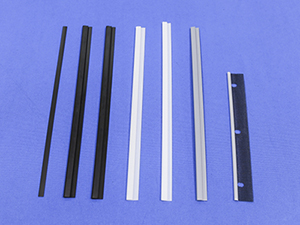

We take plastic materials and nonwoven fabrics to create outstanding custom products for clients. Currently, we focus on the production of seat covers and automotive seat components. These covers are both dustproof and waterproof. We also carry out the trimming of various films like PE, PP, LDPE, and nonwoven fabrics to make custom seat components. We offer these custom automotive interior products for brands like Nissan, Toyota, and many other car makers. Contact us today to learn more!

As a professional integrated seat cover supplier, Dongping Plastic has over 10 years of experience in car seat cover manufacturing, including front seat covers, rear seat covers, armrest covers and related plastic parts. The cover materials provided by us include leather and vinyl. We also provide OEM services for car manufacturers, truck manufacturers, bus manufacturers and manufacturers of other vehicles and accessories.

We use only the best raw materials, in leather, artificial leather, and vinyl, for use as car seat cover material. All materials must past a variety of performance tests to ensure the quality, and our testing index is done according to NES, ASTM, and GB standards, all with our production capabilities. Our factory is outfitted with 4 automatic cutting machines and 70 sewing machines, used for the production of automotive seat interiors at a monthly output of up to 1.3 million pieces. This ensures flexible manufacturing capabilities according to customer orders.

We have passed ISO/TS16949 auto quality certification system. Our plastic car seat covers are nontoxic, odorless, durable and have good toughness and tear resistance. They can be used for 3 years. We will test appearance, density of each batch before leaving factory. If their inspection are qualified we will issue certificates.

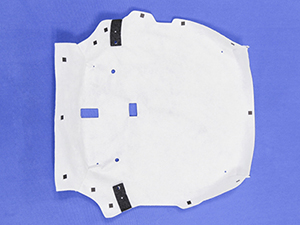

Read MoreThe automotive door moisture shield is located behind the trim panel on an automotive door. It is designed to prevent moisture from leaking into the circuit device inside the door, and thus, protect the automotive electrical components. The edge of the water shield is attached using a butyl sealant, which also protects against dust, oil and dirt.